The company, which has its headquarters in Coventry with plants in Wolverhampton, Castle Bromwich, Solihull and Halewood in Merseyside, says the pilot is an important step forward in operational efficiency and employee safety, aligning with JLR’s vision for its factories of the future.

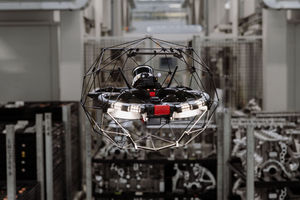

The Elios 3 drone by Flyability reaches high and confined spaces, allowing maintenance teams to inspect equipment safely from the factory floor, eliminating the need for elevated platforms and reducing risk. Operated via tablet, the drone delivers a live 3D map to identify and troubleshoot issues to help better prevent costly maintenance downtime, while freeing up employees’ time to focus on additional business critical tasks.

Nigel Blenkinsop, executive director of industrial operations at the car manufacturing business, said: “As we transform our facilities, we’re rethinking every part of our factories, including how we maintain and operate them.

“Trials like this one with advanced drone technology are helping us improve employee safety, reduce maintenance downtime and operate more efficiently. Just as importantly, they’re helping upskill our people in the latest digital technologies, ensuring our teams are part of our factories of the future.”

The drone uses Light Detection and Ranging (LiDAR) sensors to send out laser light pulses which bounce back to the drone when it hits an object. By timing how long the pulses take to return, it calculates distances to create detailed 3D maps of the surrounding environment. In addition, the drone features a thermal camera to help pinpoint overheating components or insulation failures, helping optimise energy use by detecting inefficiencies early and supporting JLR’s efforts to reduce its overall operational emissions.

Shantnu Mehta, project engineer at JLR, said: “I never imagined I’d be learning to fly drones as part of my role.

“It’s been exciting to learn how to use this technology and the skills I’ve developed will stay with me throughout my career. Being part of such an innovative project and contributing to how we’re transforming our factories for the future is something I’m genuinely proud of.”

Following successful trials at the EPMC, the next phase will take place at JLR’s Logistics Operations Centre in Solihull – a vast warehouse space equivalent to 13 football pitches. The drone at this location will be equipped with barcode scanners to automate inventory checks, replacing manual processes and enabling faster and more accurate stock updates. The technology will help improve safety, reduce errors, and support smarter decisions on space, stock levels and supply flow.

The drones initiative is part of JLR’s £3.8bn annual investment into industrial transformation, new products and technology, and is being explored through its Open Innovation programme. It also supports JLR’s Future Skills programme, which aims to train 29,000 employees in electrification and digital skills.